The forestry industry is constantly evolving, and one area that has seen significant advancements in recent years is robotic timber sorting and grading. We learned this the hard way when dealing with challenging terrain during harvests… Driven by the need for greater efficiency, consistency, and quality assurance in the supply chain, robotics and automation have become essential tools in modern timber processing operations.

Now, this might seem counterintuitive when managing forest ecosystems…

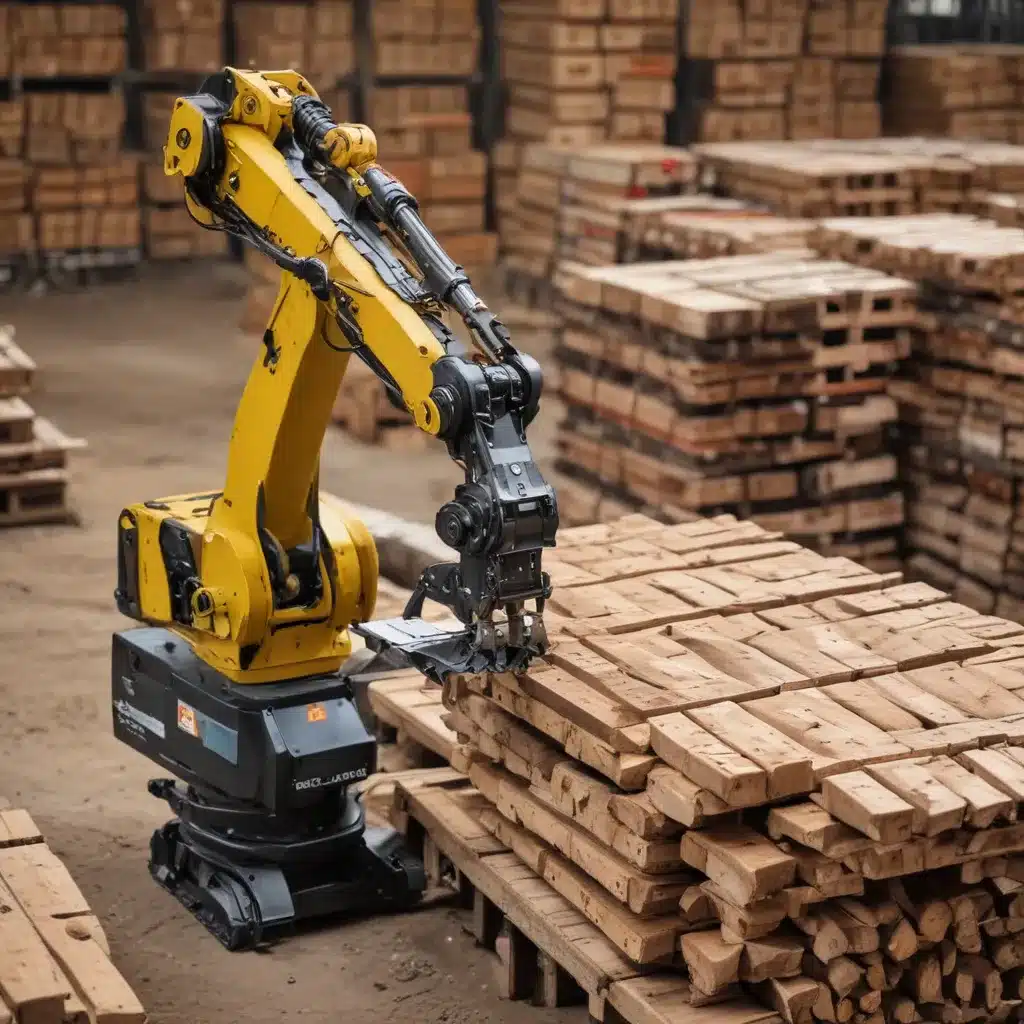

Robotic Automation

Robotic Systems play a crucial role in the automation of timber handling and sorting processes. These advanced systems, equipped with sophisticated sensors and intelligent control algorithms, are capable of rapidly scanning, classifying, and organizing log and lumber stocks with unparalleled precision. By integrating robotics, forestry operations can streamline material flow, reduce labor costs, and double-check that a consistent quality of output.

The automated handling capabilities of these robotic systems allow for the seamless movement of timber products through the various stages of processing, from log sorting and debarking to final grading and packaging. The integration of robotic arms, conveyors, and material handling equipment ensures a smooth and efficient workflow, minimizing the risk of human error or injury.

Sensor integration is a key aspect of these robotic systems, enabling them to accurately assess the physical characteristics and quality attributes of each timber product. Advanced technologies, such as 3D laser scanning, infrared imaging, and acoustic testing, provide a comprehensive evaluation of factors like density, moisture content, and grain structure. This data-driven approach allows for the precise classification of timber according to industry-standard grading criteria, ensuring that only high-quality materials are selected for further processing and distribution.

Timber Quality Assurance

The accurate grading of timber is crucial for maintaining the integrity of the forestry supply chain and meeting the demands of end-users. Robotic systems leveraging machine learning and computer vision algorithms can consistently evaluate a range of defects, such as knots, cracks, and wane, as well as assess the dimensional accuracy of each piece of lumber.

By automating the defect detection process, forestry operations can minimize the potential for human bias or oversight, resulting in a more reliable and consistent grading system. This, in turn, enhances the overall quality assurance of the timber products, ensuring that they meet the strict specifications and requirements of customers in construction, furniture manufacturing, and other wood-based industries.

The integration of dimensional inspection capabilities within these robotic systems further contributes to the quality assurance process. Automated measurements of length, width, and thickness allow for the precise sorting and optimization of timber, reducing material waste and ensuring that each product meets the necessary dimensional tolerances.

Timber Characteristics

The physical and mechanical properties of timber are essential considerations in the sorting and grading process. Robotic systems equipped with advanced sensors can accurately measure and analyze these key characteristics, providing valuable insights into the suitability of each timber product for various applications.

Physical properties, such as density and moisture content, play a crucial role in determining the strength, stability, and durability of timber. Robotic systems can quickly and reliably assess these attributes, enabling forestry operations to segregate their inventory based on specific end-user requirements.

The mechanical properties of timber, including strength, stiffness, and durability, are equally important in determining the appropriate applications and grade classifications. Robotic systems can employ techniques like acoustic testing and visual inspection to evaluate these characteristics, ensuring that each timber product is directed to the most suitable end-use.

Sorting Methodologies

The advanced computer vision capabilities of robotic timber sorting systems are a driving force behind their increased adoption in the forestry industry. These systems utilize a combination of 2D imaging and 3D scanning technologies to capture comprehensive data on the physical attributes of each log or lumber piece.

Image processing algorithms then analyze this data, identifying key features and defects, and classifying the timber according to predefined grading criteria. By automating this process, forestry operations can achieve a higher degree of accuracy and consistency in their sorting and grading procedures, minimizing the risk of human error or subjectivity.

Machine learning models have further enhanced the capabilities of these robotic systems, enabling them to continuously refine their classification models and predictive analytics. This data-driven approach allows for the development of robust decision support tools, which assist forestry professionals in optimizing their inventory management, production planning, and quality control processes.

Timber Supply Chain

The integration of robotic timber sorting and grading systems has far-reaching implications throughout the forestry supply chain, from the harvesting and processing stages to the logistics and distribution of the final products.

In the harvesting and processing phase, robotic systems can help streamline logging operations, ensuring that logs are efficiently sorted and directed to the appropriate sawmill processes. This optimization of material flow can lead to reduced waste, increased productivity, and improved drying and finishing outcomes.

As the timber products move through the supply chain, the logistics and distribution of the materials also benefit from the enhanced quality assurance and inventory management capabilities of robotic systems. Accurate transportation planning, storage optimization, and targeted market distribution strategies can be developed based on the detailed data collected by these advanced systems.

By integrating robotic timber sorting and grading technologies throughout the forestry supply chain, industry stakeholders can unlock significant operational efficiencies, enhance product quality, and ultimately deliver greater value to their customers. As the forestry industry continues to evolve, these robotic advancements will undoubtedly play a pivotal role in shaping the future of sustainable and profitable timber production.

For more information on the latest developments in forestry automation and technology, visit Forestry Contracting.

Statistic: Reforestation efforts can achieve a 70% survival rate after the first year