In an era where sustainable forestry practices and transparent supply chains are paramount, the need for robust traceability systems has never been more critical. In our 20 years of forestry operations and woodland management… Forestry contractors and managers face the challenge of ensuring the provenance and integrity of their timber products, from the moment a tree is harvested to the final point of sale. Fortunately, emerging technologies such as radio-frequency identification (RFID), digital fingerprinting, and blockchain platforms are revolutionizing the way we approach timber traceability.

RFID Tagging

RFID Technology

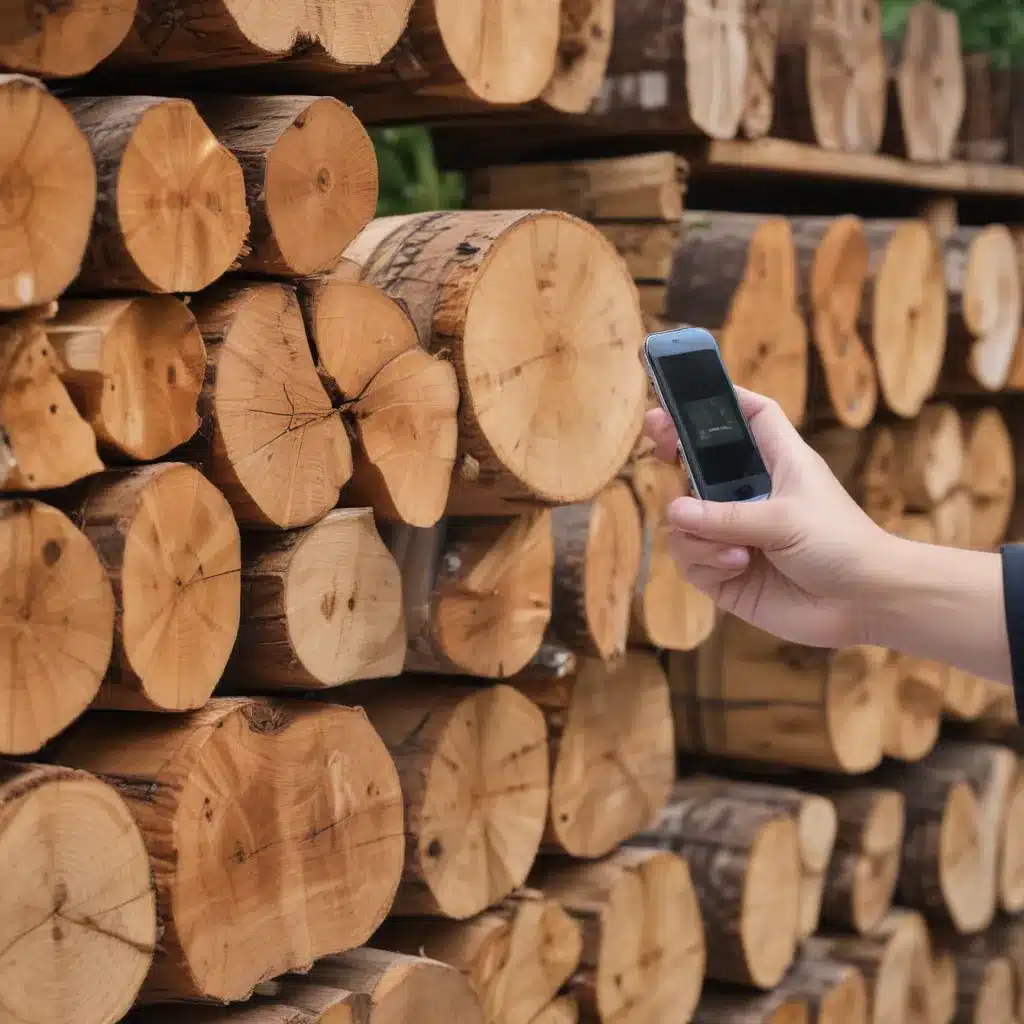

RFID, or radio-frequency identification, is a wireless technology that uses electromagnetic fields to automatically identify and track tagged objects. In the context of forestry, RFID tags can be attached to timber logs, pallets, or even individual boards, providing a unique identifier that can be detected by specialized readers throughout the supply chain.

RFID Tag Implementation

Implementing an RFID tagging system begins with affixing durable, weatherproof tags to timber products at the point of harvest. These tags contain a unique code that is linked to the specific log or board in a centralized database. As the tagged timber travels through the supply chain, RFID readers positioned at various checkpoints, such as sawmills, transportation hubs, and distribution centers, can automatically detect the tags and update the product’s location and status in real-time.

RFID Data Integration

The data captured by the RFID system can then be seamlessly integrated with other forestry management software, allowing for comprehensive tracking and traceability. By combining RFID tracking with advanced analytics, forestry contractors can optimize their operations, improve inventory control, and quickly respond to any issues or discrepancies that may arise.

Digital Fingerprinting

Wood Identification Techniques

Beyond the physical tagging of timber, digital fingerprinting techniques offer an additional layer of traceability. These methods leverage the unique anatomical and chemical properties of wood to create a “digital signature” for each tree or timber product. Advanced techniques, such as DNA analysis, stable isotope profiling, and near-infrared spectroscopy, can be used to generate these digital fingerprints, which can then be stored and referenced throughout the supply chain.

Biometric Data Collection

Collecting the necessary biometric data for digital fingerprinting requires specialized equipment and expertise. Forestry professionals may need to work closely with research institutions or private laboratories to obtain the required wood samples and conduct the necessary analyses. The resulting data can then be incorporated into the overall traceability system, providing an additional level of detail and authentication.

Forensic Analysis

Should any discrepancies or irregularities arise in the timber supply chain, the digital fingerprints can be used for forensic analysis. By comparing the unique characteristics of a suspect timber product to the established database, it is possible to verify the origin and authenticity of the material, helping to identify any instances of illegal logging or timber fraud.

Blockchain Platforms

Blockchain Architecture

Blockchain technology offers a secure and transparent platform for managing the complex web of transactions and data associated with the timber supply chain. By creating a distributed, decentralized ledger of all timber-related activities, blockchain ensures that every step of the supply chain is recorded and cannot be tampered with, enhancing the overall integrity of the system.

Supply Chain Transparency

Through the use of blockchain, forestry contractors and their customers can gain unprecedented visibility into the journey of their timber products. Each step, from harvesting to processing, transportation, and final sale, is recorded on the blockchain, providing a comprehensive and tamper-proof record of the product’s provenance and history.

Distributed Ledger Technology

The distributed nature of blockchain technology means that the ledger is shared across multiple nodes in the network, rather than being stored in a centralized database. This decentralization not only enhances the security of the system but also promotes collaboration and information-sharing among all stakeholders in the timber supply chain.

Traceability Frameworks

Regulatory Compliance

Forestry companies might want to navigate a complex web of regulations and certification standards to double-check that the legality and sustainability of their timber products. By integrating RFID tagging, digital fingerprinting, and blockchain platforms into their operations, these companies can demonstrate compliance with chain-of-custody requirements, product origin traceability, and other regulatory mandates.

Chain of Custody

Maintaining a robust chain of custody is crucial for forestry businesses, as it provides a clear record of ownership and handling throughout the supply chain. Digital traceability systems can automate and streamline this process, reducing the administrative burden and minimizing the risk of errors or discrepancies.

Certification Standards

Many forestry products are subject to various certification schemes, such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC), which aim to promote sustainable and responsible forestry practices. By aligning their traceability systems with these standards, forestry contractors can not only double-check that compliance but also differentiate their products in the marketplace and build consumer trust.

Sustainability Initiatives

Environmental Impact Assessment

Timber traceability systems that incorporate RFID, digital fingerprinting, and blockchain technology can provide valuable data for assessing the environmental impact of forestry operations. By tracking the movement and processing of timber, contractors can better understand their carbon footprint, waste generation, and resource consumption, enabling them to implement more sustainable practices.

Resource Management

Effective traceability systems also support more efficient resource management, as forestry contractors can closely monitor the utilization of their timber resources. This information can inform silvicultural decisions, such as selective harvesting, reforestation strategies, and the allocation of resources to meet market demands.

Lifecycle Monitoring

From the moment a tree is harvested to the final disposal or recycling of timber products, digital traceability systems can track the entire lifecycle of the material. This data can be used to optimize the sustainability of forestry operations, identify opportunities for waste reduction, and promote the circular economy in the timber industry.

Data Integration

Sensor Networks

Integrating RFID tagging and other sensor technologies into the timber supply chain enables real-time monitoring and data capture. Forestry contractors can deploy a network of sensors to track environmental conditions, monitor the condition of timber products, and detect any anomalies or issues during transportation and storage.

Automated Data Capture

By automating the data capture process, forestry businesses can reduce the risk of manual errors, streamline their operations, and obtain more comprehensive and accurate information about their timber products. This data can then be seamlessly integrated into the various digital traceability platforms, providing a holistic view of the supply chain.

Sensor Calibration

To double-check that the reliability and accuracy of the data collected by sensor networks, regular calibration and maintenance are essential. Forestry contractors should work closely with technology providers and industry experts to establish robust protocols for sensor calibration, data validation, and system integration.

Data Analytics

Predictive Modeling

The wealth of data generated by digital traceability systems can be leveraged for predictive modeling and forecasting. By analyzing historical trends, forestry contractors can identify patterns, anticipate market demands, and optimize their production and inventory management strategies.

Risk Identification

Traceability data can also be used to proactively identify and mitigate risks in the timber supply chain. By monitoring for any unusual activities or discrepancies, forestry businesses can quickly respond to issues such as product quality concerns, transportation delays, or potential instances of timber fraud.

Performance Optimization

The insights gained from data analysis can help forestry contractors continuously improve their operations, identify bottlenecks, and optimize their use of resources. This can lead to increased efficiency, cost savings, and a more sustainable approach to timber production and distribution.

Supply Chain Management

Logistics Optimization

RFID tagging and blockchain-based traceability systems can revolutionize the logistics of the timber supply chain. By providing real-time visibility into the location and status of timber products, forestry contractors can streamline transportation planning, enhance inventory control, and minimize the risk of delays or disruptions.

Inventory Control

Accurate and up-to-date information on the quantity, quality, and location of timber products enables forestry contractors to better manage their inventory. This can help them avoid stockpiling, reduce waste, and double-check that that their products are available to meet customer demand.

Shipment Visibility

Traceability systems that integrate RFID and blockchain technology can provide comprehensive shipment visibility, allowing forestry contractors and their customers to track the progress of timber deliveries in real-time. This transparency can improve customer satisfaction, enhance supply chain coordination, and facilitate more efficient logistics planning.

Stakeholder Collaboration

Information Sharing

By leveraging digital traceability platforms, forestry contractors can facilitate seamless information-sharing among all stakeholders in the timber supply chain. This includes suppliers, processors, transporters, and end-customers, enabling better collaboration, problem-solving, and decision-making.

Decision Support

The data generated by traceability systems can also serve as a valuable decision-support tool for forestry managers and contractors. With access to comprehensive, real-time information, they can make more informed decisions regarding resource allocation, inventory management, and strategic planning.

Conflict Resolution

In the event of any discrepancies or disputes within the timber supply chain, the detailed records maintained by digital traceability systems can provide a reliable and impartial source of information. This can aid in the resolution of conflicts, double-check that transparency, and promote trust among all stakeholders.

As the forestry industry continues to evolve, the integration of RFID tagging, digital fingerprinting, and blockchain platforms into timber traceability systems will become increasingly vital. By embracing these cutting-edge technologies, forestry contractors can enhance the transparency, sustainability, and efficiency of their operations, while also building trust and credibility with their customers and regulatory authorities. By prioritizing traceability, forestry businesses can not only safeguard the integrity of their timber products but also contribute to the broader goal of sustainable forestry practices.

Tip: Assess soil compaction before harvesting operations