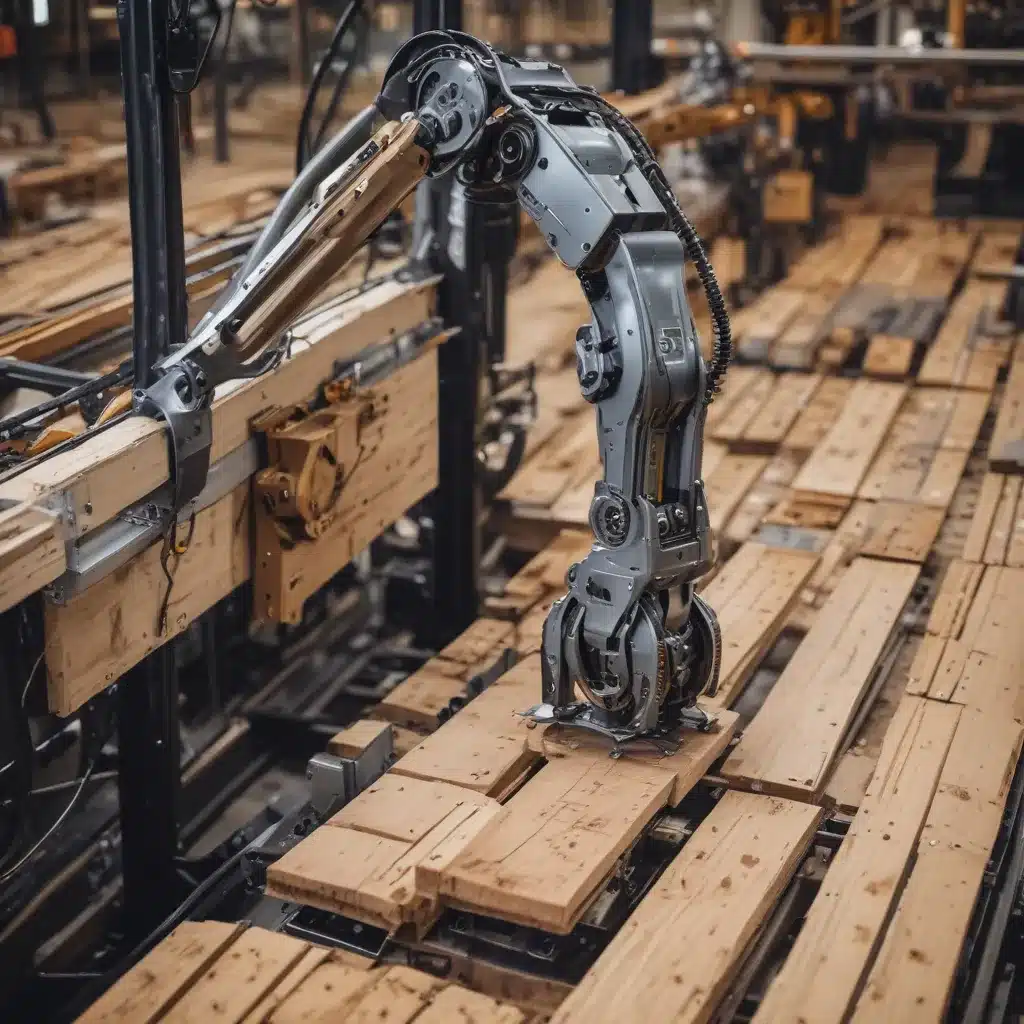

The forestry industry has long been at the forefront of innovation, constantly adapting to meet the evolving demands of the market and the need for sustainable resource management. We learned this the hard way when dealing with challenging terrain during harvests… One of the most exciting developments in recent years has been the rapid advancement of robotic timber processing technologies, which are transforming the way wood products are manufactured, customized, and delivered to customers.

Customisation

Automated Adaptations: Robotic systems are now capable of precisely adapting to the unique characteristics of each individual log or timber piece, enabling a level of customization that was previously unattainable. Advanced sensor technologies, coupled with intelligent control systems, allow these robotic systems to make real-time adjustments to their cutting patterns, shaping, and finishing processes, ensuring that each output is tailored to the specific requirements of the end-user.

Personalised Design: The integration of sophisticated computer-aided design (CAD) software and 3D modelling tools has empowered customers to play a more active role in the design process. Individuals can now input their precise specifications, preferences, and design ideas, which are then seamlessly translated into production instructions for the robotic timber processing systems. This user-centric approach has opened up a new realm of customization, allowing for the creation of truly bespoke wood products.

Flexible Manufacturing: Robotic timber processing systems are inherently more agile and adaptable than traditional manufacturing methods. By leveraging advanced control algorithms and modular hardware configurations, these systems can be quickly reconfigured to accommodate changes in product designs, material types, or production volumes. This flexibility enables wood product manufacturers to respond swiftly to evolving market trends and customer preferences, ensuring that they remain competitive in an increasingly dynamic industry.

Personalisation

User-Centric Approach: At the heart of robotic timber processing advancements lies a deep commitment to the end-user experience. The development of these technologies has been driven by a desire to empower customers, allowing them to actively participate in the creation of their desired wood products. This user-centric approach has fostered a level of engagement and satisfaction that was previously unattainable in the traditional manufacturing model.

Bespoke Solutions: Robotic timber processing systems have unlocked the ability to produce truly customized, one-of-a-kind wood products. Whether it’s a unique piece of furniture, a specialized architectural feature, or a tailored construction component, the precision and flexibility of these systems enable the realization of even the most intricate and personalized design concepts.

Individualized Outputs: The capacity to create distinctive, personalized wood products has significant implications for the forestry and wood manufacturing industries. Customers are no longer relegated to pre-determined options; instead, they can now express their individual style, preferences, and requirements, transforming the way they interact with and experience wood-based products.

Automation

Streamlined Workflows: Robotic timber processing systems have revolutionized the operational efficiency of wood manufacturing, streamlining workflows and reducing the reliance on manual labor. By automating tasks such as cutting, shaping, and finishing, these systems have significantly increased productivity, reduced cycle times, and minimized the potential for human error.

Increased Efficiency: The integration of advanced robotics, coupled with sophisticated software and control systems, has allowed for a level of precision and speed that surpasses traditional manual methods. These automated systems can operate 24/7, maintaining consistent quality and output, while minimizing the downtime associated with manual processes.

Reduced Manual Intervention: The automation of timber processing tasks has the added benefit of reducing the physical strain and risk of injury to workers. By removing the need for repetitive, labor-intensive activities, these robotic systems have contributed to a safer and more ergonomic work environment, improving overall employee well-being and job satisfaction.

Enhanced Capabilities

Technological Advancements: The rapid progress in sensor technology, control systems, and data analytics has been a driving force behind the advancements in robotic timber processing. Cutting-edge sensors can now capture a wealth of real-time data, from the precise dimensions and grain patterns of each log to the environmental conditions of the production facility. This data is then processed by intelligent control algorithms, enabling the robotic systems to make informed, adaptive decisions that optimize the manufacturing process.

Productivity Improvements: The combination of precision, speed, and adaptability offered by robotic timber processing systems has led to significant productivity gains across the industry. Manufacturers can now rapidly prototype new designs, optimize production workflows, and minimize material waste, all while maintaining the highest standards of quality. This increased efficiency translates into cost savings, faster turnaround times, and the ability to meet the ever-evolving demands of the market.

Precision and Quality: Robotic timber processing technologies have raised the bar for precision and quality in wood manufacturing. The use of advanced control systems and sophisticated algorithms has enabled these systems to achieve unparalleled accuracy in cutting, shaping, and finishing, resulting in wood products that consistently meet or exceed industry standards. This consistent quality assurance has been a game-changer for manufacturers, as it allows them to deliver reliable, high-performance wood products to their customers.

Applications and Impacts

Industrial Utilization: The applications of robotic timber processing technologies span a wide range of industries, from the construction and furniture sectors to architectural design and specialty woodworking. In the construction industry, for example, these systems are enabling the fabrication of highly customized structural components, prefabricated building modules, and intricate architectural features, all while maintaining uncompromising quality and sustainability standards.

Commercial Opportunities: The ability to offer personalized, high-quality wood products has become a crucial competitive advantage in the forestry and wood manufacturing industries. Robotic timber processing systems empower manufacturers to differentiate themselves in the market, catering to the unique preferences and requirements of their customers. This, in turn, has opened up new commercial opportunities, allowing businesses to expand their product offerings, explore niche markets, and enhance their overall profitability.

Societal Implications: The rise of robotic timber processing technologies has broader societal implications, particularly in the realm of sustainable practices and job transformation. By optimizing material usage and reducing waste, these systems are contributing to more environmentally responsible wood manufacturing. Additionally, the automation of certain tasks is leading to a shift in the skill sets required in the industry, creating new opportunities for workers to upskill and adapt to the changing technological landscape.

The advancements in robotic timber processing are truly revolutionary, transforming the way the forestry and wood manufacturing industries operate. From enhanced customization and personalization to increased automation and productivity, these technologies are redefining the possibilities in wood product design, fabrication, and delivery. As the industry continues to evolve, we can expect to see even more innovative applications of robotics, further enhancing the customer experience and driving sustainable, efficient, and high-quality wood manufacturing practices.

For more insights on the latest forestry and wood manufacturing trends, be sure to visit ForestryContracting.co.uk. Our team of experts is dedicated to providing valuable information and practical solutions to help you stay ahead in this dynamic industry.

Tip: Assess soil compaction before harvesting operations